Description

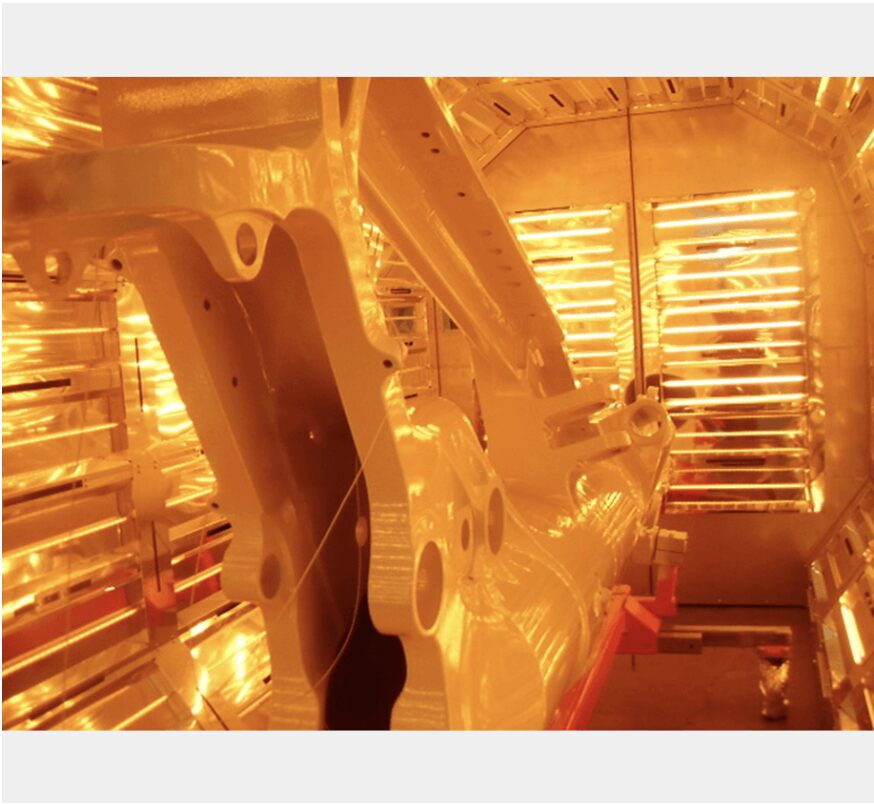

Infrared Booster Ovens

These versatile, modular ovens are engineered for compatibility with all coating types and can be tailored to accommodate various part sizes and shapes. They are especially effective for increasing line speeds and managing multiple control zones to meet productivity goals. Features include energy-efficient, instant on/off emitter control.

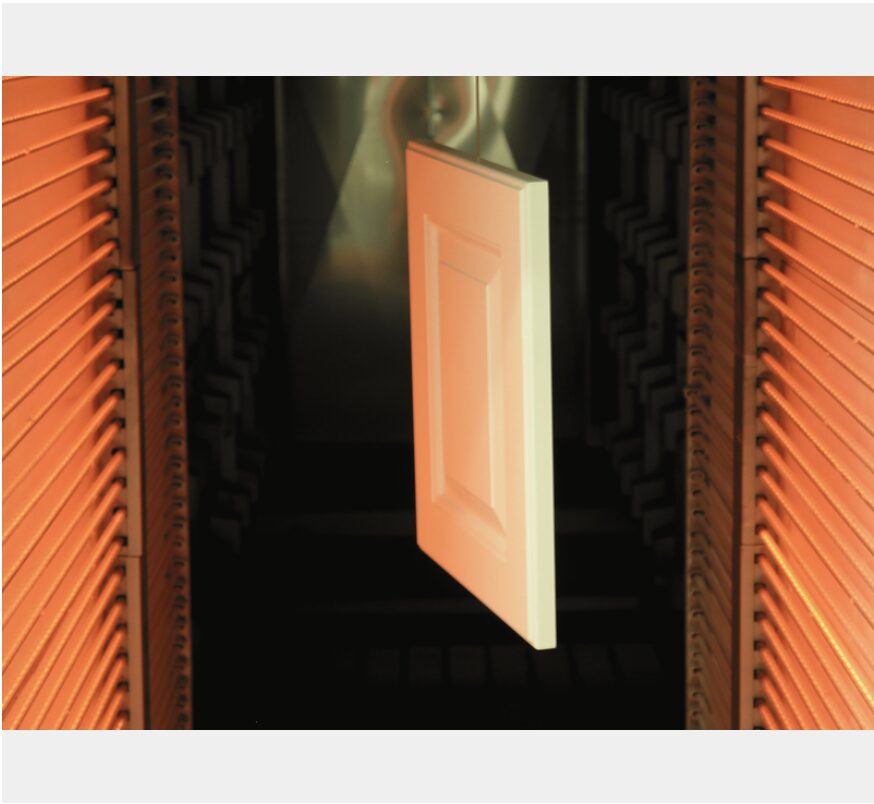

BGK Smart Oven

Designed for on-site testing of coatings and processes, the BGK Smart Oven provides valuable data to aid in process development. It simulates a precise and repeatable testing environment for accurate results.

BGK Glass Oven Systems

- Flat Glass Oven and Drying Systems: Tailored to meet diverse glass market needs, these systems use high-intensity infrared technology and feature a compact design with T3 short-wave infrared emitters, offering exceptional drying capabilities and energy efficiency.

- Glass Preheat Ovens: These ovens provide efficient wavelength control for rapid and uniform heating, improving bond strength at the gasket and glass interface. Closed-loop temperature control ensures the glass reaches the desired temperature before the injection molding process.

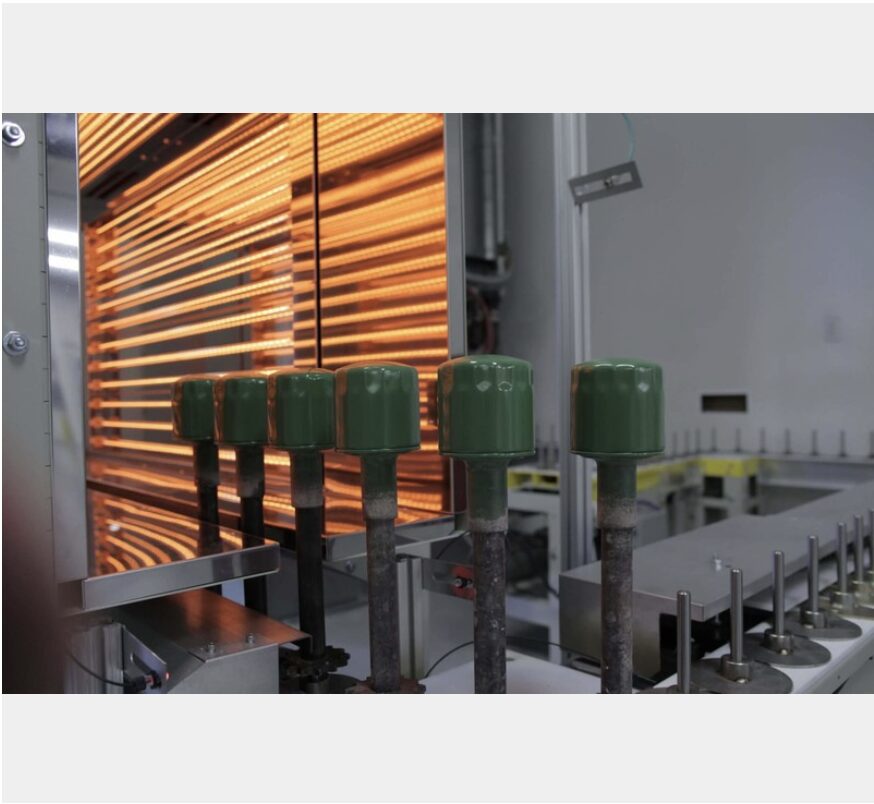

Flash Off Ovens

Used between coating applications, flash-off ovens allow coatings to bake or dry, facilitating initial solvent release. This process helps prevent bubbling or blistering from insufficient evaporation and reduces rework by ensuring proper evaporation before entering a curing oven or a subsequent coating process.